The landscape of industrial automation thrives on seamless and secure data exchange. At the heart of this communication revolution lies the OPC Unified Architecture (UA), and a critical component within this architecture is the Opc Ua Server. Since its inception in 2008, OPC UA has provided a platform-independent, service-oriented framework, consolidating the functionalities of legacy OPC Classic specifications into a unified and extensible solution. The OPC UA Server is the key to unlocking this potential, acting as the central point for accessing industrial data in a standardized and secure manner.

Understanding the OPC UA Server

An OPC UA Server is essentially the gateway to industrial data within the OPC UA framework. It’s a software application that implements the OPC UA protocol to expose data and functionalities from various industrial devices and systems to client applications. Think of it as a translator and data provider, converting proprietary communication protocols into a standardized OPC UA format, making information accessible to a wide range of client applications, regardless of the underlying hardware or operating system.

The core functionalities of an OPC UA Server are robust and designed for industrial needs:

- Data Access: Providing organized and structured access to real-time and historical data. OPC UA Servers represent data in a hierarchical address space, similar to files and folders, making it easy for clients to discover and utilize both simple and complex data structures.

- Events & Alarms: Notifying clients of significant occurrences, system alerts, or changes in data values based on predefined criteria. This ensures timely responses to critical events within industrial processes.

- Methods: Allowing client applications to trigger actions or execute programs on the server side. This enables remote control and interaction with industrial equipment and processes through the OPC UA Server.

Unlike its predecessors, OPC Classic servers, the OPC UA Server transcends the limitations of DCOM, offering platform independence and enhanced security, making it suitable for modern, distributed industrial systems.

OPC Foundation Offerings for OPC UA Technology, including resources, getting started guides, and market-specific information.

OPC Foundation Offerings for OPC UA Technology, including resources, getting started guides, and market-specific information.

Key Features and Benefits of OPC UA Server

The widespread adoption of OPC UA Server technology is driven by its compelling features and benefits:

Platform Independence: OPC UA Servers are engineered to operate across diverse platforms. Whether it’s traditional PC hardware, cloud-based infrastructure, Programmable Logic Controllers (PLCs), or embedded micro-controllers, an OPC UA Server ensures seamless communication. It supports various operating systems like Windows, Linux, and even mobile platforms, breaking down the barriers of platform-specific dependencies in industrial communication.

Enhanced Security: Security is paramount in industrial settings, and OPC UA Servers are built with robust security mechanisms. They are designed to be firewall-friendly and incorporate a comprehensive suite of security controls, including:

- Encryption: Secure data transmission through various encryption levels, protecting sensitive industrial data.

- Authentication: Utilizing X.509 certificates to verify the identity of both clients and servers, controlling which applications and systems can connect.

- Auditing: Logging user and system activities, providing a detailed audit trail for security monitoring and compliance.

Functional Equivalence and Extensibility: OPC UA Servers are not just replacements for OPC Classic servers; they are functionally superior and designed for future innovation. They encompass all the functionalities of OPC Classic while providing an extensible architecture. This means new technologies, security algorithms, or communication protocols can be integrated into OPC UA Servers without disrupting existing systems, ensuring long-term compatibility and adaptability.

Information Modeling Prowess: OPC UA Servers excel at transforming raw data into meaningful information. Their advanced information modeling framework, based on object-oriented principles, allows for the creation of complex, multi-level data structures. This enables industries to represent intricate systems and processes in a structured and easily understandable manner, facilitating better data analysis and decision-making.

Getting Started with OPC UA – Resources and Guides from the OPC Foundation.

Getting Started with OPC UA – Resources and Guides from the OPC Foundation.

OPC UA Server in Action: Use Cases and Applications

The versatility of OPC UA Server technology translates to a wide array of applications across industries.

- Cross-System Data Exchange: In complex industrial environments, OPC UA Servers act as vital intermediaries, enabling data flow between disparate systems – from sensors and actuators on the factory floor to enterprise-level applications. This unified communication layer streamlines operations and improves data visibility.

- IIoT and Industry 4.0 Enabler: As industries move towards the Industrial Internet of Things (IIoT) and Industry 4.0, OPC UA Servers are foundational. They provide the necessary infrastructure for connecting industrial assets to the cloud and enabling advanced analytics, remote monitoring, and predictive maintenance.

- Industry-Specific Applications: Numerous industries, from energy to manufacturing, leverage OPC UA Servers for specialized applications. Companion specifications built on OPC UA cater to specific domain needs, ensuring interoperability and standardized data exchange within those sectors.

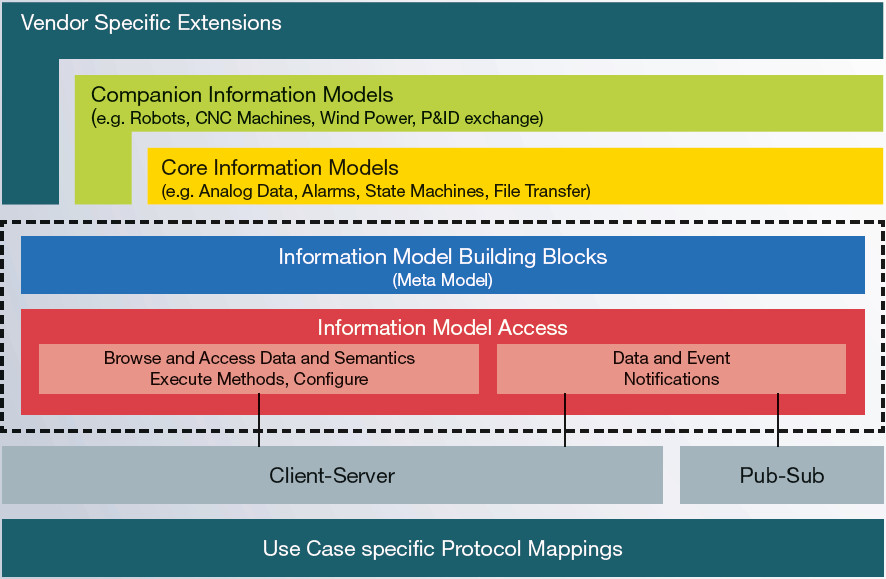

OPC UA Architecture Layers – Illustrating the extensible and secure framework for industrial communication.

OPC UA Architecture Layers – Illustrating the extensible and secure framework for industrial communication.

Conclusion

The OPC UA Server is more than just a communication tool; it is a cornerstone of modern industrial communication. Its platform independence, robust security, extensibility, and powerful information modeling capabilities make it an indispensable component for businesses seeking to unlock the full potential of their industrial data. As industries continue to embrace digitalization and interconnected systems, the OPC UA Server will undoubtedly remain a critical technology, driving efficiency, innovation, and security in the evolving landscape of industrial automation.