Navigating the world of RC car servos, enthusiasts are constantly seeking the perfect balance of performance, reliability, and value. AGFRC, a brand that has been on the scene since 2009, initially garnered attention for its competitively priced servos, particularly within online communities like RCTech. This user’s journey with the AGFRC A80BHM servo, designed for 1/8 scale applications, however, took an unexpected turn, highlighting potential issues with durability and after-sales support. This review delves into a firsthand experience that raises crucial questions about the long-term reliability of Agfrc Servos, specifically the A80BHM model, and the company’s handling of customer concerns.

The Initial Appeal: Performance and Price

The allure of AGFRC servos, in this case, began with their attractive pricing. Acquiring an A80BHM servo for around $45, thanks to discounts, seemed like a smart move. The initial impressions were positive. The servo showcased impressive smoothness, power, and speed. This user deployed several AGFRC servos across different RC car classes, including the A80BHM in a TEKNO SCT410. Other models like the A62BLS were used in 1/10 buggies and mini truggies. For a brief period, these servos appeared to be an exceptional deal, delivering high performance at a fraction of the cost of established brands.

Gear Stripping Issues and Rising Costs

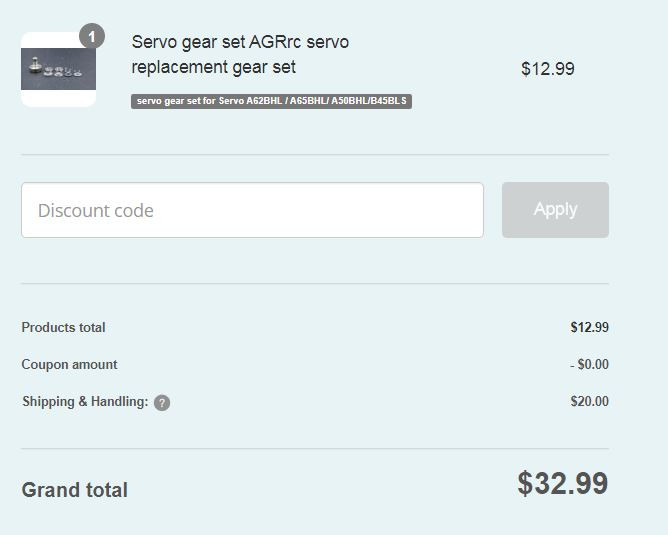

The honeymoon phase, however, was short-lived. Within four months, the A62BLS servo in a mini truggy experienced gear stripping – not once, but three times. While replacement gear sets were available, the exorbitant shipping costs pushed the price of each repair to nearly $33. This rapidly escalated the total cost of ownership. What began as a budget-friendly servo was quickly becoming an expensive proposition. It’s crucial to note that for a 1/10 mini truggy, a servo with around 200 oz-in of torque is generally recommended. The A62BLS, rated at 201 oz-in, was theoretically on the edge of being adequate, but the repeated gear failures suggested otherwise, especially under the stress of a mini truggy application.

AGFRC Servo Stripped Gears

AGFRC Servo Stripped Gears

To address the gear stripping issues, an upgrade to the A65BHL servo (350 oz-in) in the mini truggy was implemented. Fortunately, this servo performed reliably for over nine months without gear failures. The other A62BLS servos in 1/10 buggies also fared better, experiencing fewer gear stripping incidents. Despite the initial setback with the A62BLS and the high cost of replacement gears, the user remained cautiously optimistic about the AGFRC brand, even stocking up on gear sets as a precaution.

The A80BHM Servo Failures and Customer Service Breakdown

The focus then shifted to a new build, a TEKNO EB48 2.0 buggy. The manufacturer’s recommendation of a servo with at least 300 oz-in of torque pointed towards the AGFRC A80BHMW, boasting a 500 oz-in rating. Despite a significant price increase of 69% compared to previous purchases, the perceived performance and added waterproof feature of the A80BHMW made it seem like a worthwhile investment.

However, after approximately ten race days, the first A80BHM servo failed abruptly during a race. There was no motor movement, suggesting an internal electrical issue. Initially, the lack of a servo saver was considered a potential contributing factor. Two more A80BHM servos were subsequently purchased – one as a replacement and another for a future 1/8 truggy project. This time, a servo saver was installed. Yet, to the user’s dismay, the replacement A80BHM servo also failed after another ten race days. This second failure exhibited different symptoms: the motor still moved under no load, but produced only a whining sound when connected to the servo horn under load. Gear replacement did not resolve the issue, indicating a potential motor or internal mechanical failure beyond gear stripping.

Misleading Advertising and Lack of Support

Sharing these findings on the RCTech forum led to AGFRC’s awareness of the issue. Helen Deng from AGFRC contacted the user, seemingly offering customer support. However, the interaction quickly soured. Instead of offering a warranty solution or a free upgrade, Helen suggested purchasing the A81BHM servo, implying the A80BHMW was unsuitable and blaming the user for choosing the “wrong” servo. This was particularly frustrating because the A80BHMW, with its 500 oz-in rating, was marketed for 1/8 scale applications by resellers. The product page where the servo was purchased explicitly listed it for 1/8 cars.

AGFRC’s response was to remove the 1/8 scale designation from their official product page for the A80BHM servo, effectively shifting blame onto the user and employing a bait-and-switch tactic. The core issue remained unaddressed: a servo marketed with a high torque rating and implied 1/8 scale suitability failed prematurely in a typical 1/8 buggy application. The lack of warranty support and the attempt to deflect responsibility left the user deeply disappointed and questioning AGFRC’s commitment to customer satisfaction and accurate product representation.

Conclusion: Reliability Concerns and Buyer Beware

While the user intends to continue using the existing AGFRC servos in 1/10 scale vehicles, the experience with the A80BHM servos has been a turning point. The repeated failures, coupled with the unsatisfactory customer service response, have eroded trust in the brand. The user explicitly states they will not repurchase AGFRC products and will refrain from recommending them.

For 1/8 scale applications, the user has reverted to SRT servos, specifically the SRT BH927S, which had previously proven reliable in a TEKNO EB48.4 buggy for two years without issues. Although SRT servos are more expensive upfront, the long-term cost, considering the AGFRC servo failures and replacements, actually becomes more economical and provides peace of mind.

This experience highlights the critical importance of servo reliability, especially in demanding 1/8 scale applications. It also underscores the need for manufacturers to stand behind their products with robust warranties and responsive customer support. The user’s takeaway is clear: buyer beware when considering AGFRC servos for 1/8 scale applications, particularly the A80BHM model. The seemingly attractive initial price may be overshadowed by potential durability issues and a lack of adequate support when problems arise. Consider investing in more established and reliable brands, like SRT, for long-term performance and peace of mind in the demanding world of RC racing.