This section provides a comprehensive overview of chalk lines, detailing their diverse applications and fundamental principles. Explore a curated list of 11 prominent chalk line manufacturers and their respective company rankings. Below are the top-rated chalk line companies as of March 2025: 1. Tenet Corp, 2. Shinwa Rules Co., Ltd., 3. MEUNIER TOOLS.

Understanding the Functionality of a Chalk Line

A carpenter uses a chalk line to mark a straight line on a piece of wood, demonstrating the tool's primary function in woodworking and construction.

A carpenter uses a chalk line to mark a straight line on a piece of wood, demonstrating the tool's primary function in woodworking and construction.

A chalk line is fundamentally a marking tool utilized across various trades to establish long, straight lines on surfaces. While commonly associated with carpentry, its utility extends far beyond woodworking, proving invaluable in numerous applications where precision marking is required.

Diverse Applications of Chalk Lines

Chalk lines are indispensable tools for achieving straight lines in a wide array of fields. Their applications span across:

- Construction: Marking out building layouts, foundations, and framing lines.

- Equipment Installation: Ensuring precise alignment for machinery and fixtures.

- Electrical Work: Establishing straight runs for conduit and wiring.

- Shipyard Tasks: Marking cutting lines on large metal sheets and ship components.

- Flooring Installation: Creating guidelines for tile, hardwood, and laminate flooring layouts.

- Landscaping: Defining straight edges for pathways, garden beds, and fences.

- Drywall Installation: Marking cut lines for drywall sheets to ensure accurate fitting.

- Painting: Creating straight lines for paint edges, especially on walls and ceilings.

The Operational Principle of a Chalk Line

The mechanism of a chalk line is relatively simple yet effective. It comprises a robust housing that contains chalk-soaked cotton, a spool for winding the string, and a crank, often integrated into a hook, to secure the string’s end. The housing is typically constructed from durable resin, while the line itself is commonly made of resilient nylon, and the internal padding utilizes absorbent cellulose cotton to hold the chalk.

Diagram illustrating the internal components of a chalk line, showcasing the chalk reservoir, string spool, and crank mechanism for line deployment and retraction.

Diagram illustrating the internal components of a chalk line, showcasing the chalk reservoir, string spool, and crank mechanism for line deployment and retraction.

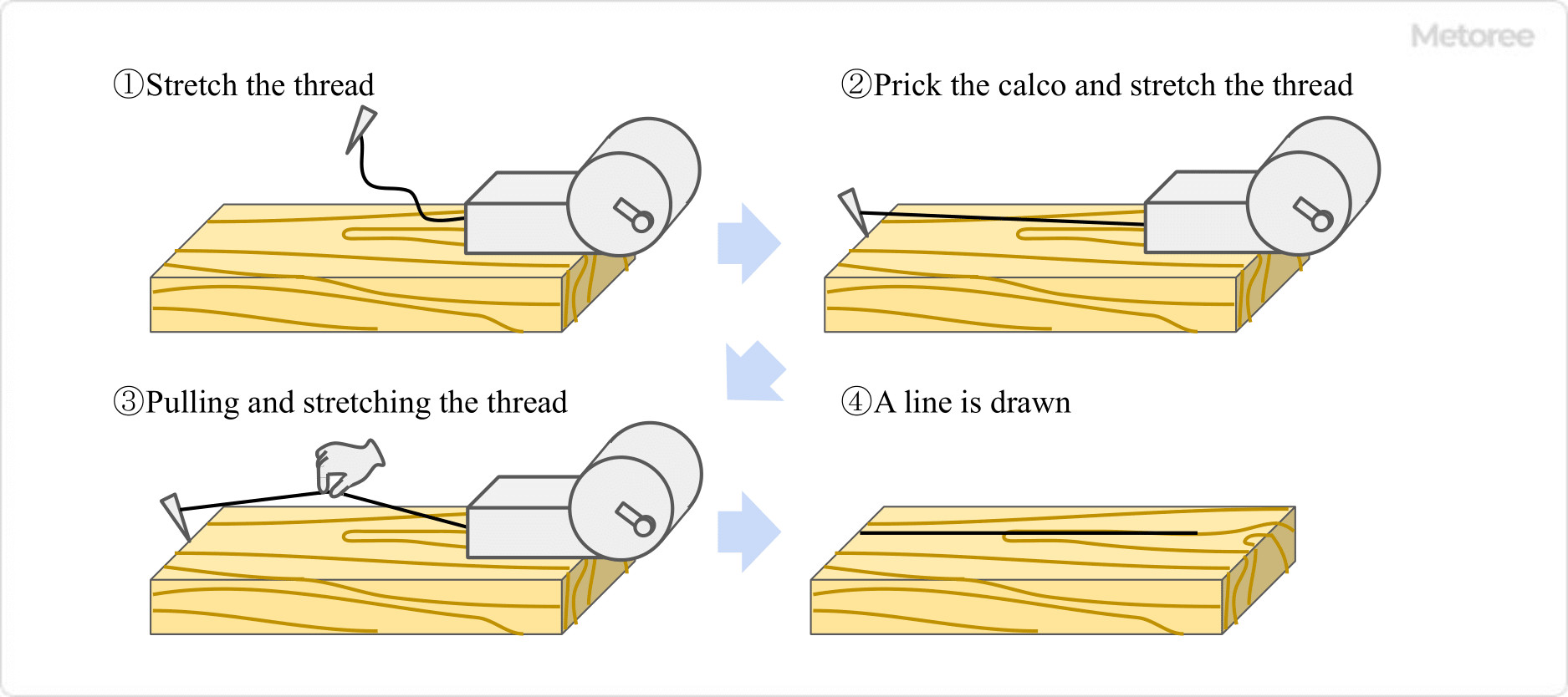

To use a chalk line, the hook or crank is anchored at the desired starting point. The string is then extended to the opposite end point, pulled taut, and snapped against the surface. The chalk transferred from the string leaves a crisp, visible line, guiding cuts, installations, or alignments with accuracy.

Key Considerations When Selecting a Chalk Line

Choosing the right chalk line involves evaluating several features to match specific needs and applications.

1. Integrated Thread Restrainers

Certain chalk line models incorporate a thread restrainer directly on the housing. This feature eliminates the need to manually hold the chalked line, promoting cleaner and more efficient operation. Two primary types of restrainers exist:

- Diagonal Cut Type: This design offers excellent visibility of the line’s tip and ensures stable line holding.

- Crane-Neck Type: Featuring a rod extending from the chalk line, this type excels in confined spaces like corners, where manual line holding is challenging. However, the narrow holding point can be less stable compared to the diagonal cut type.

2. Line Retraction Mechanisms

Chalk lines are available with two main types of thread retraction: manual and automatic.

- Automatic Retraction: Offers speed and convenience, rewinding the line rapidly. However, forceful retraction can sometimes lead to chalk spillage. Opting for models with deceleration or anti-spill features mitigates this issue.

- Manual Retraction: While slower, manual rewind provides greater control. Models with multiple gears enhance rewind speed, making manual retraction less laborious.

3. Line Material and Thickness

The characteristics of the chalk line’s thread are crucial.

- Thick Thread: Produces bold, highly visible lines, ideal for pattern marking. However, it consumes chalk more quickly.

- Thin Thread: Creates finer lines, suitable when minimal marking is desired. Thinner threads are more prone to breakage, so selecting a chalk line with a robust thread is essential.

4. Chalk Reservoir Design

For infrequent use, chalk within the reservoir can solidify. Choosing a chalk line with a tightly sealed ink jar prevents chalk drying, ensuring consistent performance over time.

5. Chalk Type and Color

Black India ink is the standard for chalk lines, providing high contrast and durability. However, specialized applications may require different colors.

- Colored Chalks (White, Vermilion, Blue): Used for color-coding or when black markings are undesirable. Standard inks are typically permanent.

- Vermilion Chalk (Bengara-based): Often used on finished lumber or logs, this type of chalk is designed to be wiped clean, leaving minimal residue.

- Powder Chalk: Easily erasable, powder chalk is well-suited for finished surfaces where permanent marks are unwanted. It also performs better on rough surfaces like concrete and metal where liquid inks may not adhere effectively.

Selecting the appropriate chalk type is critical for achieving the desired marking outcome and surface compatibility.

Leading Chalk Line Manufacturers

*Includes distributors and related entities.

Sort by Features

- Default

- Company Size: Largest First

- Year Founded: Oldest First

- Year Founded: Earliest First

Sort by Area

- United States of America

- Canada

- Japan

- Spain

Top Chalk Line Manufacturer Rankings

*Includes distributors and related entities. Rankings as of March 2025.

| Rank | Company | Click Share |

|---|---|---|

| 1 | Tenet Corp | 14.8% |

| 2 | Shinwa Rules Co., Ltd. | 11.5% |

| 3 | MEUNIER TOOLS | 9.8% |

| 4 | CX Connexion | 9.8% |

| 5 | Metálicas Plásticas Jar S.l. | 8.2% |

| 6 | Kara Company, Inc | 8.2% |

| 7 | Wallboard Trim & Tool. | 8.2% |

| 8 | SCN Industrial, Inc. | 8.2% |

| 9 | Stanley Black & Decker, Inc. | 8.2% |

| 10 | Keson Industries, Inc. | 6.6% |

Derivation Method: Rankings are based on click share within the chalk line category as of March 2025. Click share is calculated as the proportion of total clicks for each company relative to the total clicks across all companies listed.

Company Age – Newly Established

- CX Connexion: 2007 (Established 18 years ago)

- Wallboard Trim & Tool.: 1997 (Established 28 years ago)

- SCN Industrial, Inc.: 1978 (Established 47 years ago)

Company Age – Long-Standing History

- Kara Company, Inc: 1967 (Established 58 years ago)

- Keson Industries, Inc.: 1968 (Established 57 years ago)

- Metálicas Plásticas Jar S.l.: 1969 (Established 56 years ago)

Chalk Line Manufacturers in the United States

*Includes distributors and related entities.

Global Distribution of Chalk Line Manufacturers by Country

*Includes distributors and related entities.

| Country | Number of Companies | Share (%) |

|---|---|---|

| United States of America | 4 | 44.4% |

| Canada | 3 | 33.3% |

| Japan | 1 | 11.1% |

| Spain | 1 | 11.1% |